Cover The Third Rail!

The third rail and current collector technology used by the Chicago Transit Authority (CTA) is antiquated and barbaric. The recent death of a coworker who fell on one is just one of many reasons why.

The hazard of an uncovered 600 Volts DC piece of iron has been—and will continue to be—unnecessarily injuring and killing countless workers and riders.

For the second largest public transportation agency in the United States, there is simply no excuse to not cover the top of the third rail.

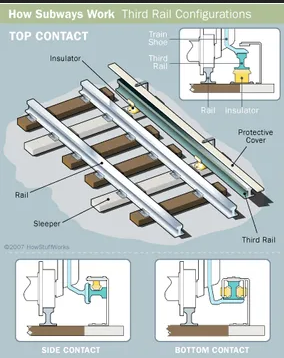

The graphic at left by HowStuffWorks.com shows three types of covered third rail technology in existence. Ironically, it has no reference to the uncovered—and unsafe—third rail used by the CTA and some smaller public transit agencies. Why should it? It is totally unsafe.

The bottom contact type is superior for safety. It also makes it difficult for trespassers to commit suicide through contact with the third rail.

See this abbreviated list of transit systems with covered third rails (not including other countries):

Washington D.C.

New York City

San Francisco

Atlanta

Philadelphia

It is time to leave the stone age of rail safety and get with the modern age. The CTA can no longer hide behind rules, blame the workers, the unwitting riders, trespassers and do nothing to eliminate the hazard.

Safety goes far beyond the writing of rules and punishing rule violators. It starts with hazard elimination.

The unions must back demands with action to ensure the safety of Trackmen, Flagmen, Switchmen, Carpenters, Iron Workers, Painters, Signal Maintainers, Motormen, Customer Assistants and ANY worker who may be near the third rail.

Any union president who refuses to support—and organize around—such a demand is an apologist for the blame-the-worker status safety culture. They should be put up on charges and removed from office.

Yes, it will cost money to replace the ancient system on the tracks and rail cars. However, there can be no price too high when it comes to the sanctity of life. Also, we have had enough of union leadership helping employers save money when it comes to our safety and dignity.

Compared to the trillions of tax-payer dollars spent on wars in Ukraine, Afghanistan and Iraq, converting to covered third rail with bottom contact types—and refitted rail car current collectors—is a small cost.

Below are important links about third rail hazard mitigation.

Covered Third Rail Technology for side, top bottom current collectors:

https://www.pandrol.com/us/product/third-rail-system/

Custom Third Rail Cover Board manufacturer which can possibly accommodate the legacy system so the CTA could just retrofit the rail cars:

https://www.masstransitmag.com/rail/product/10067764/enduro-third-rail-cover-board

Case study for third rail covers:

https://www.strongwell.com/case-study-rail-system-requires-miles-of-fiberglass/

Eliminating Blame the Worker Safety Culture:

https://www.ueunion.org/stwd_safetyblame.html

Comments

Post a Comment

Please post your uncensored comments and questions.